Aptflex F48

The NPL’s acoustic absorber Aptflex F48 has been designed to meet the need to reduce reflections in sub MHz frequency test tanks.

The NPL’s acoustic absorber Aptflex F48 has been designed to meet the need to reduce reflections in sub MHz frequency test tanks.

If you have any specific questions about this product, please contact us.

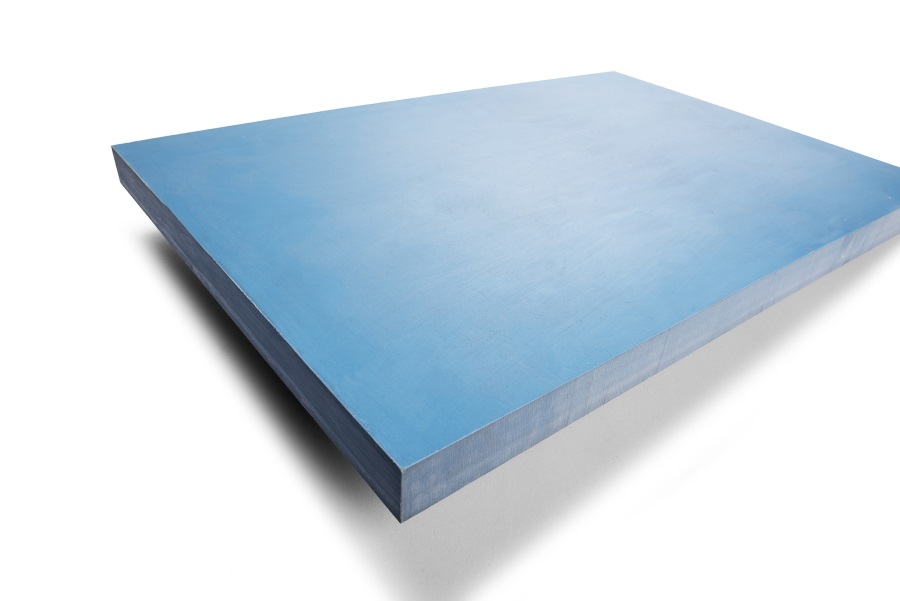

The Aptflex F48 is an acoustic absorbing tile designed to meet the requirements of applications in frequency range 50 kHz to 1.5 MHz. It is a microbubble filled, pre-cast polyurethane sheet that provides a cost effective balance between echo reduction and insertion loss.

For long toneburst or continuous-wave ultrasonic applications, acoustic output measurements or ultrasonic testing in general can be strongly affected by reflections or echoes from test tank walls. To overcome this, test tanks are coated with ultrasonically absorbent linings which must be of low ultrasonic reflection yet highly absorbing to ultrasound. The Aptflex F48 material is specifically designed to meet this requirement. Its simple design, being a single-ply layer, ensures that the material is the cost-effective solution for coating large areas such as the walls of an ultrasonic test tank.

* Minimum order quantities apply if there is no stock or if longer expiry dates are required.

This limits or affects the performance at low frequencies, as IL goes down with frequency.

At 100 kHz, single pass insertion loss of a 26.5 mm thick layer of the material is 21 dB, which means that double (the wave which goes through, bounces off the tank wall and comes back out) is 42 dB (0.8% amplitude).

The insertion loss increases rapidly with frequency in the following way: 500 kHz: 100 dB single pass; 1 MHz: 200 dB single pass and 3 MHz: >500 dB single pass.

Note the structure shown below; 200 kHz is caused by the reflected wave from the front surface interfering with the reflected wave from the back surface of the tile.

The echo-reduction limits or affects the performance of the tank wall lining at high frequencies (>1 MHz).

For a 26.5 mm tile the ER is better than 20 dB below 0.5 MHz. The peak in the ER is sensitive to temperature and it is possible to match the performance to the temperature of the customer’s test tank. If matched, then it is possible to obtain an ER better than 30 dB.

At 1 MHz, the echo-reduction of a 26.5 mm tile is 20 dB (10% reflected amplitude) and at 3 MHz, it is 15 dB (18% reflected amplitude). Careful angling of the flat panels will improve performance greatly. Anything twice reflected will come down in amplitude to 1% at 1 MHz and about 3% at 3 MHz.

If you would like more information about this product, please get in touch by phone, email or enquiry form.

Alternatively complete our enquiry form below.

Telephone:

Email:

Precision Acoustics Ltd

Hampton Farm Business Park

Higher Bockhampton

Dorchester

Dorset DT2 8QH

United Kingdom

© Copyright Precision Acoustics Ltd. 2025

Registration number: 02466435

VAT number: GB529840128

Feedback | Terms & Conditions | Privacy Policy | Site by Click 71

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |