0.5 mm needle hydrophone

Hydrophones of 0.5 mm have been widely used in the measurement of high-frequency ultrasound.

Hydrophones of 0.5 mm have been widely used in the measurement of high-frequency ultrasound.

Our needle hydrophones are available to buy direct through our secure online shop.

With the exceptional signal-to-noise ratio, we recommend the use of our 0.5 mm needle hydrophone for measurements where signal amplitudes are expected to be particularly low.

However, these probes can be used for higher frequency measurements (particularly of very weak signals) but in such situations the inherent directivity and spatial averaging characteristics of a 0.5 mm aperture means that care should be taken in interpreting data.

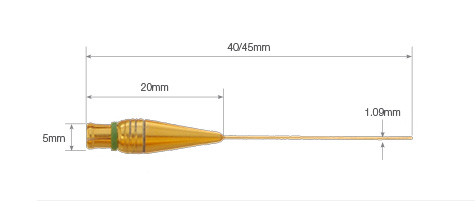

All dimensions are in mm. All probes are hand made and as such there is always some variation between individual devices.

Please contact us if the actual dimensions are critical to your work.

| Output impedance: | 18 pF± 3 pF |

| Typical probe sensitivity: | 300 nV/Pa (equivalent to -250.5 dB re 1V/uPa) averaged over the range 2 MHz to 12 MHz when measured at the output of a correctly terminated HP1 submersible preamplifier |

| Sensitivity tolerance: | Sensitivity variation between individual probes is approximately ±3 dB |

| Typical frequency response: | Flat (±2 dB): 3 MHz to 15 MHz Flat (±4 dB): 1 MHz to 15 MHz Minimum calibration frequency 100 kH |

| Sensor material: | 9 micron thick gold electroded Polyvinylidene fluoride (PVdF) film |

| Sensor dimension: | 0.5 mm diameter disc |

* Precision Acoustics reserves the right to change the specification without notice.

A simple guide can be found here “Simple guide to making ultrasonic intensity measurements” or if you are in the UK you might be interested in our “Hydrophone users course” in the training section

Hydrophones can be used in castor oil or mineral oil. The hydrophone is constructed from PVdF which although resilient can be damaged by some chemicals. Consult our web page properties of poled piezo-electric PVdF film.

All hydrophones should be soaked before use. Although most hydrophones stabilise after about 10 minutes, our recommendation is to soak for 1 hour so that the output stabilises before measurements are taken.

Hydrophones should be removed from the water as soon as possible and we advise that if they are left immersed longer than 24 hours they are removed as soon as possible and dried out.

If possible rinse the hydrophone tip in distilled water at the end of a measurement session and leave to air dry or place in a warm oven at no more than 50 °C. Do not touch the hydrophone tip.

Immerse the hydrophone tip in lemon juice and then rinse in distilled or running water.

The input and output from your measurement equipment should be terminated with 50 Ω.

It doesn’t matter whether you measure it as a power or voltage ratio – you’ll get the same dB result.

Three 9 v batteries in series will give enough voltage but they will not last very long and may cause changes in the measured signal. All DC couplers supplied after March 2008 are supplied with a small desktop power supply suitable for use with the hydrophone system. Contact us if you wish to purchase a PSU for use with older systems.

No – it simply powers the preamp and removes the dc component from the returned signal.

Yes, you can feed a test signal in and measure the response. You will need to use a 50 Ω terminator at the input if you use a 50 Ω signal source. You will also need to use 50 Ω input on your oscilloscope.

Precision Acoustics manufactures transducers over the frequency range 0.2 MHz to 50 MHz using a variety of different materials

The sensitivity is simply a conversion factor between pressure and voltage. If you measure peak-to-peak voltage and apply the conversion factor, you will measure peak-to-peak pressure. If you measure rms voltage and apply the conversion factor, you will measure rms pressure. The same will be true for peak positive, peak negative, etc.

If you would like more information about this product, please get in touch by phone, email or enquiry form.

Alternatively complete our enquiry form below.

Telephone:

Email:

Precision Acoustics Ltd

Hampton Farm Business Park

Higher Bockhampton

Dorchester

Dorset DT2 8QH

United Kingdom

© Copyright Precision Acoustics Ltd. 2025

Registration number: 02466435

VAT number: GB529840128

Feedback | Terms & Conditions | Privacy Policy | Site by Click 71

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |